A duct rodder eases the action of pushing a rod or multiple of rods in a pipe, conduit, drain, or a duct to lay a cable or clear it. A duct rodder is a mechanical tool for supporting cabling in pipelines or other types of conduits.

At Sintaductrodder, we are going to show you how to use duct rodder for cable laying in the conduit.

Cable laying requires correctness and skills for proper installation in buildings, underground, and in other locations, duct rodders make this possible.

Duct rodder is useful in measuring space before installation, preparation before laying of cable, and collecting cables from another side of the conduit. The duct rodder makes the tasks easier and ensures optimal results achievement.

In any work you undertake, you have to prepare and know the tools necessary for the task fully. The same goes when laying cables and duct rodders makes it easier and saves a lot of time in the procedures.

Accessories that come with a duct rodder

- Clevis ends or Shackle fitting – for fitting on the tapered head to provide a larger pulling loop for rope or pull line attachment.

- Rod ends – they attach to the end fitting on the duct rod, also known as tapered head. They come as a standard accessory for duct rodders.

- Roller guides – To guide the duct rod around bends, duct misalignments, and sweeps. It is also necessary when the conduit has other cables. They are also known as Flexible guide heads.

- Splice Connectors. – For connecting lengths of duct rod from either side of the conduit. This is only applicable in large conduits and cannot negotiate bends.

- Swivel Connectors.- for connecting two lengths of duct rods

Uses of duct rodder

- The length of the tool combined with its frame makes it excellent for placing smoothing through, pulling something from, or reaching the other side of a small space or passage like a conduit, pipe, drain, or a duct. The purpose of this is to prepare for installation, cleaning, or pulling something from the other end.

- Measuring by placing the rod inside the conduit by attaching a pull tape or using the digital reader provided

- Duct rodder is also good in the Inspection of a conduit or passage when checking for blockages or other problems or in determining if the conduit is clear. This is made possible by attaching a camera at its tip.

- Duct rodders are also good at cleaning conduits that are narrow and hard to find.

- Pulling cables inside a conduit

- Pulling thread lines along a conduit

A duct rodder like any other tool uses are many, but its misuse can lead to damage of the equipment. Thus you should use it for the prescribed procedures to ensure its durability and efficiency.

Safety operating procedures for duct rodders

- The tools, equipment, and materials we manufacture and supply come with an instruction manual for safe use. We recommend our duct rodders for use by trained personnel. This ensures longevity in the use of our tools and ensuring accident-free during operation.

- You should read the safety and operating instructions carefully and understand them before using the duct rodder from sintaductrodder.com.

Operating instructions

- Position the duct rodder in the location where the conduit, pipe, duct, or pipe is. Ensure the ground is stable where your duct rodder is.

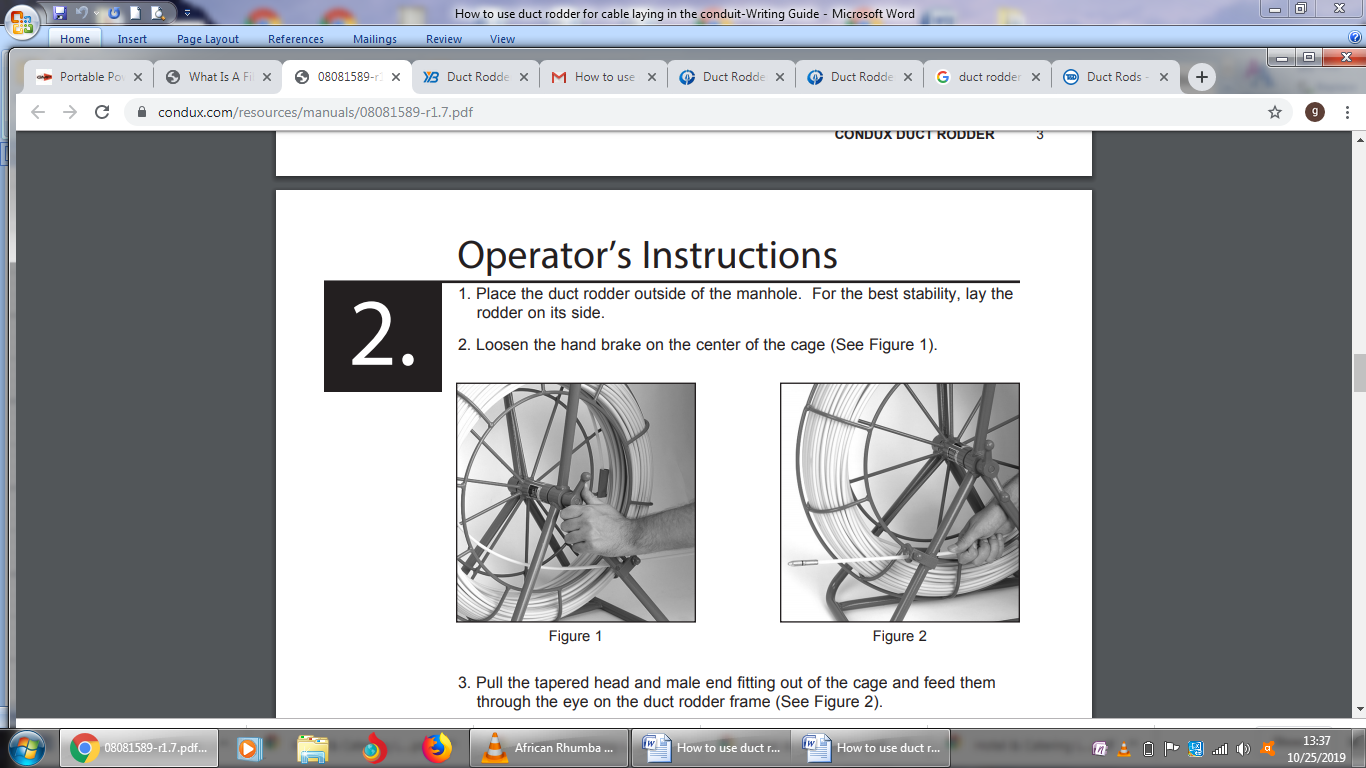

- Place the duct rodder on its side.

- Loosen the clamp or break to ease the movement of the duct rodder. The break restricts the moving of the duct rodder when pulling. To use duct rodder for cable laying in the conduit, you can either position it lying on its side for horizontal rotation or when standing for vertical rotation.

- Pull the tapered head and male end fitting out of the duct rodder cage. Feed the end through the eye on the duct rodder frame.

- Exchange the tapered head with the other optional end fittings for the specific job at hand. For example, if you want to attach a camera end.

- Insert the duct rod into the maintenance hole and the conduit gently.

- Start pushing the duct rod into conduit with your hand. This may require some force to enable it to negotiate bends. You should not, at any time, use mechanical means when pushing the duct rod.

Note: The size of the conduit you are working on determines the size of the duct rod to use. We at Sintaductrodder have different specifications of duct rods for different conduits. You should consult our chart for the right size. A larger rod is not capable of negotiating bends while a smaller one will buckle.

- When you reach the end of the duct rod and still have conduit, join another duct rod to increase the length of the first one by swivel coupling.

Note: You may use the brake (clamp) on the duct rodder frame to slow the speed of the cage or to prevent it from turning when feeding the duct rod.

- On reaching the desired end of the conduit, detach any optional accessories like the camera and attach the tapered head. You may also attach a shackle fitting if required.

- Attach the pull line or the rope to the tapered head and shackle.

- From the entry point of the duct rod in the conduit, start pulling it out while feeding it back into the duct rodder cage. This requires more than one person or more for proper feeding of the duct rod back into the cage of the duct rodder. You should never use mechanical means to pull the duct rod out of the conduit.

Caution!! You cannot spin the cage of the duct rodder to get the rod back into it. The rod must be pushed through the eye into the cage.

- After finally pulling the entire length of the duct rod, remove the rope or the pull line attached at the end. Remove the shackle fitting from the tapered head or any other accessory attached.

- Feed the end of the duct rod through the eye back into the cage of the duct rodder. The duct rodder should always be stored when the duct rod is fully inside but never with the end protruding through the eye.

Conclusion

The How to use duct rodder for cable laying in the conduit document explains and gives out the proper way of using duct rodders.

Like any other machine in use for any work, you, as the user should ensure that you have the necessary training to acquire the skills of operation.

Ensure regular, proper maintenance for optimum performance and longer life of your machine. During operation, ensure handling of the duct rod is according to the instructions to avoid inconveniences and damage to the rod and the duct rodder itself.